Business Outline & Agency

Business Outline & Agency list

- Engine OVHL & Repair

- Aux. machinery repair

- Propeller, Thruster & Rudder repair

- Carpentry/Electric/Pipe/Steel outfitting works & hull repair

- Chemical cleaning & reconditioning of heat exchangers

- Conversion or Remodeling of passengers ships

- Repair of Naval ships & equipment (incl. subsea diving equipment)

- Repair of Maritime Police ships & equipment

- KANAGAWA F.O & L.O Strainer sales & service agent

- AKASAKA engine OVHL & Repair

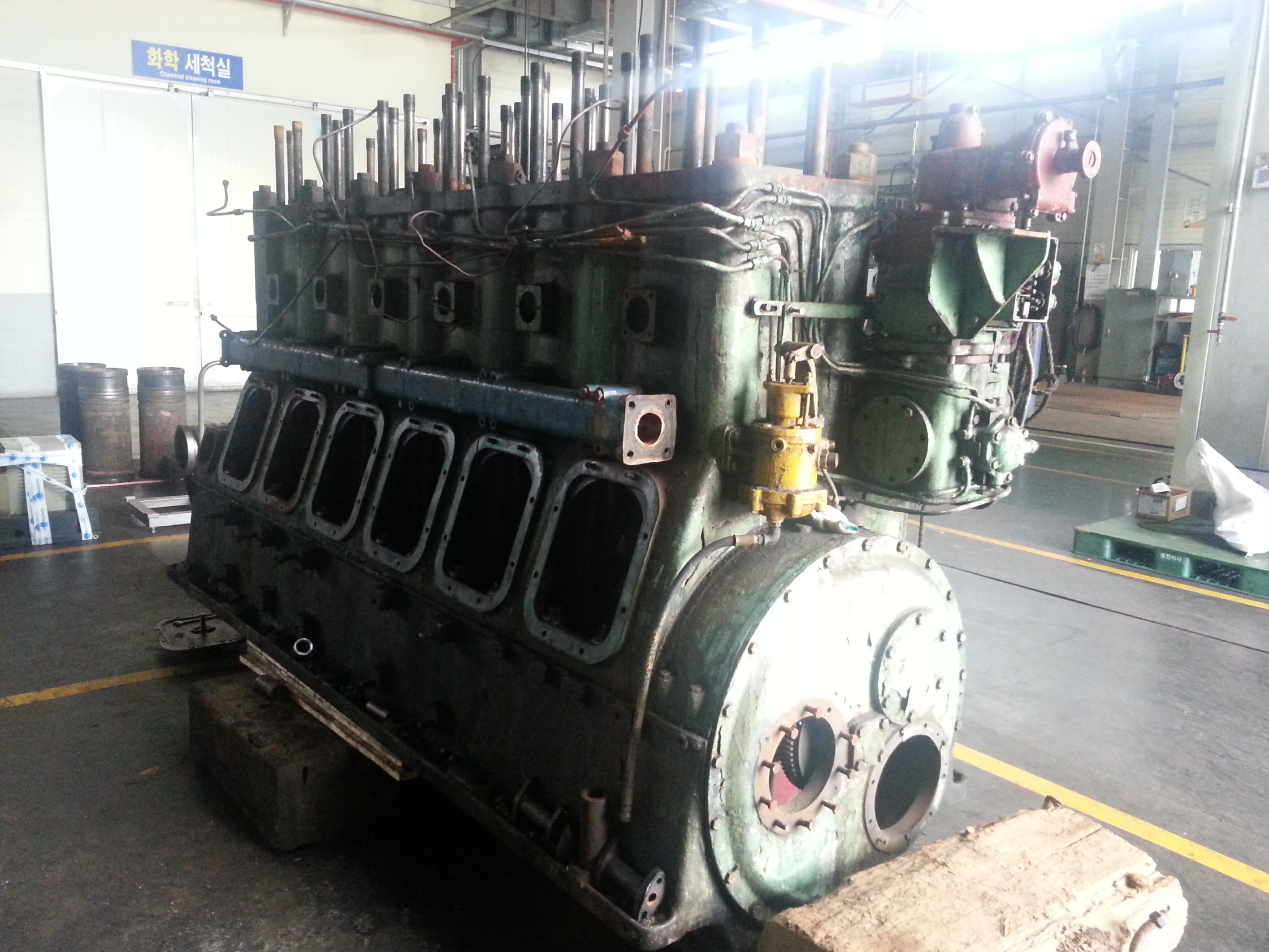

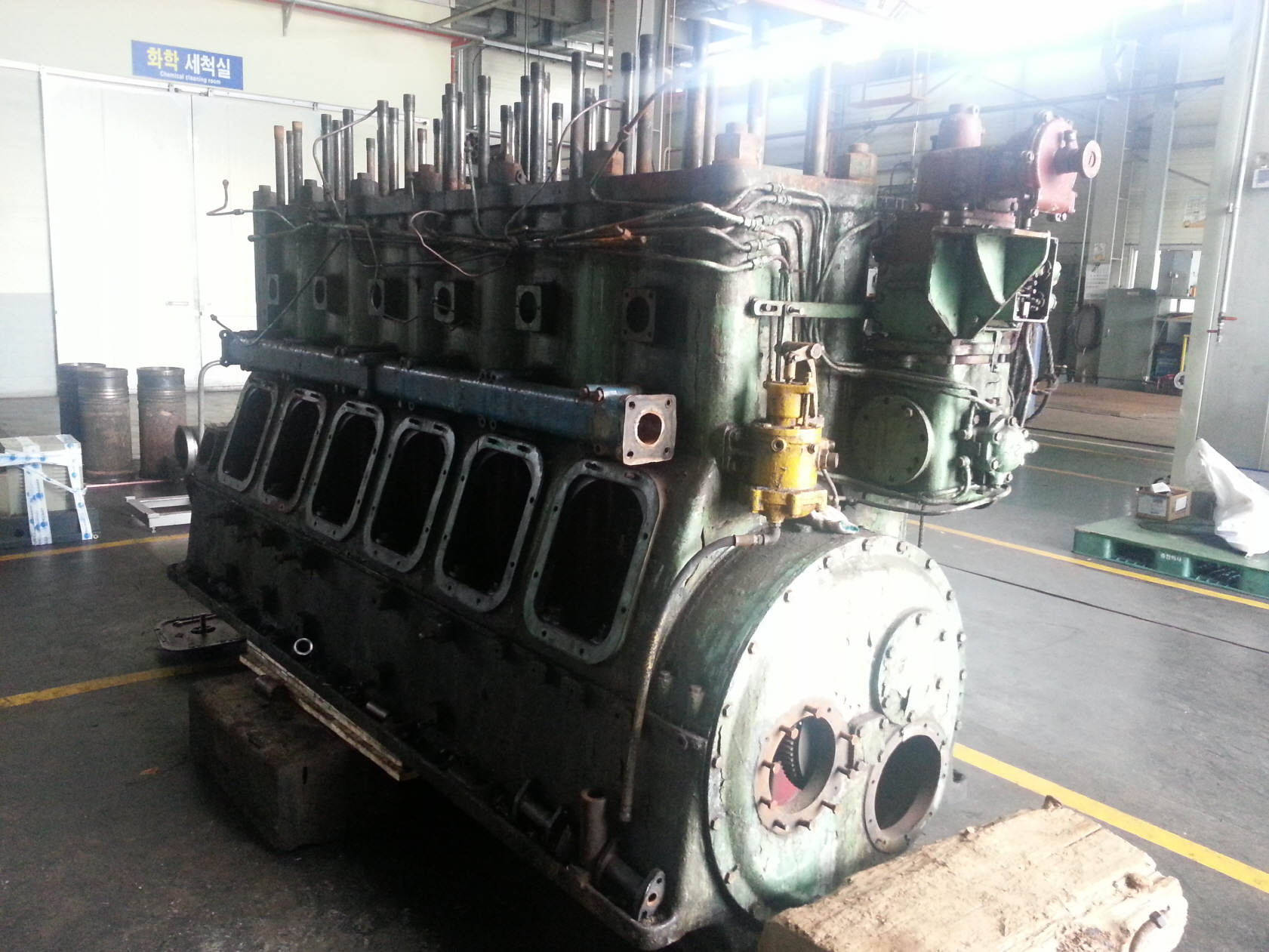

Engine OVHL & Repair

▶Manin engine repairing

- Assembling after maintenance of Crank shaft

- Assembling after maintenance of Cylinder Block

- P/T Check after cleaning of Cylinder Head

▶Auxiliary engine repairing

- Repairing of Crank shaft for Generator engine

- Repairing of Sole plate for Generator engine

- Repairing of Cylinder Block for Generator engine

Team : Ship & Machinery Repair Team

In charge : S.Y.Baek Director

Tel : 82-51-413-7701

E-mail : jmis@jonghap.co.kr

Aux. machinery repair

▶Manin engine repairing

- Assembling after maintenance of Crank shaft

- Assembling after maintenance of Cylinder Block

- P/T Check after cleaning of Cylinder Head

▶Auxiliary engine repairing

- Repairing of Crank shaft for Generator engine

- Repairing of Sole plate for Generator engine

- Repairing of Cylinder Block for Generator engine

Team : Ship & Machinery Repair Team

In charge : S.Y.Baek Director

Tel : 82-51-413-7701

E-mail : jmis@jonghap.co.kr

Propeller, Thruster & Rudder repair

- Take out of st'bd propeller shaft

- propeller blade grinding

- Detaching & manufacturing of port & st'bd seal & liner

Team : Ship & Machinery Repair Team

In charge : S.Y.Baek Director

Tel : 82-51-413-7701

E-mail : jmis@jonghap.co.kr

Carpentry/Electric/Pipe/Steel outfitting works & hull repair

- Maker

- KANAGAWA KIKI KOGYO CO., LTD

- Major Product

- Major Product : F.O & L.O AUTO BACKWASH FILTER(NOTCH WIRE TYPE FOR M/E & G/E), F.O & L.O CARTRIDGE FINE FILTER, and variety of Filter.

- Major Business

- Major Business : SALES AGENT & A/S CENTER IN KOREA(RETROFIT, FILTER SUPPLY FOR NEW BUILDING SHIP, Cleaning of filter, etc.)

- In charge

-

Headquarter(Namhang) Consulting

Senior

- Team :

- Ship & Machinery Repair Team

- In charge :

- S.H.Han Manaver

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

Deputy

- Team :

- Ship & Machinery Repair Team

- In charge :

- S.K.Kwon Assistant Manager

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

Revolution Machinery Division

Senior

- Team :

- Turbocharger Service Team

- In charge :

- K.S.Hong General Manager

- Tel :

- 82-51-413-4277

- E-mail :

- infoturbo@jonghap.co.kr

Deputy

- Team :

- Turbocharger Service Team

- In charge :

- K.S.Hong General Manager

- Tel :

- 82-51-413-4277

- E-mail :

- infoturbo@jonghap.co.kr

- Field practice

-

- Team :

- Ship & Machinery Repair Team

- In charge :

- M.H.Bae Senior Foreman

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

Chemical cleaning & reconditioning of heat exchangers

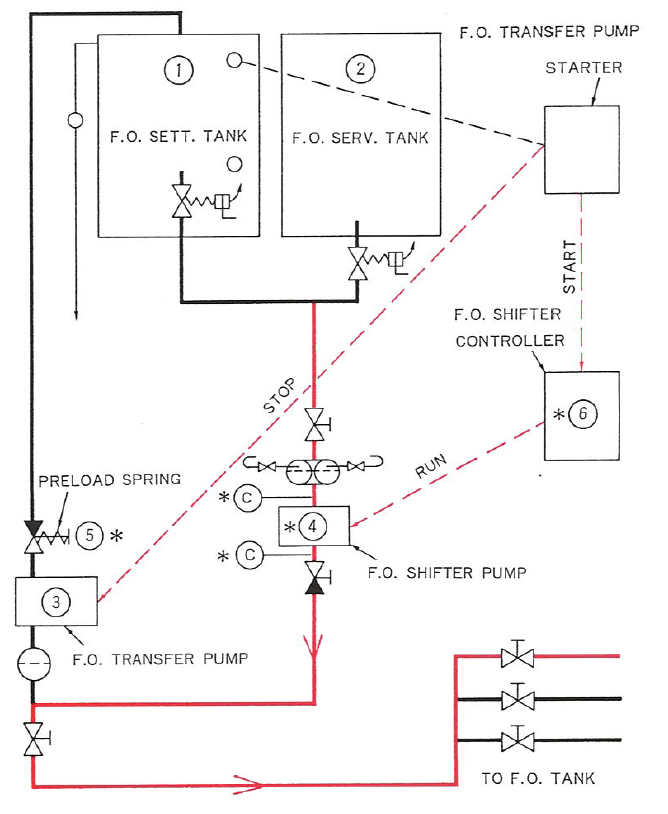

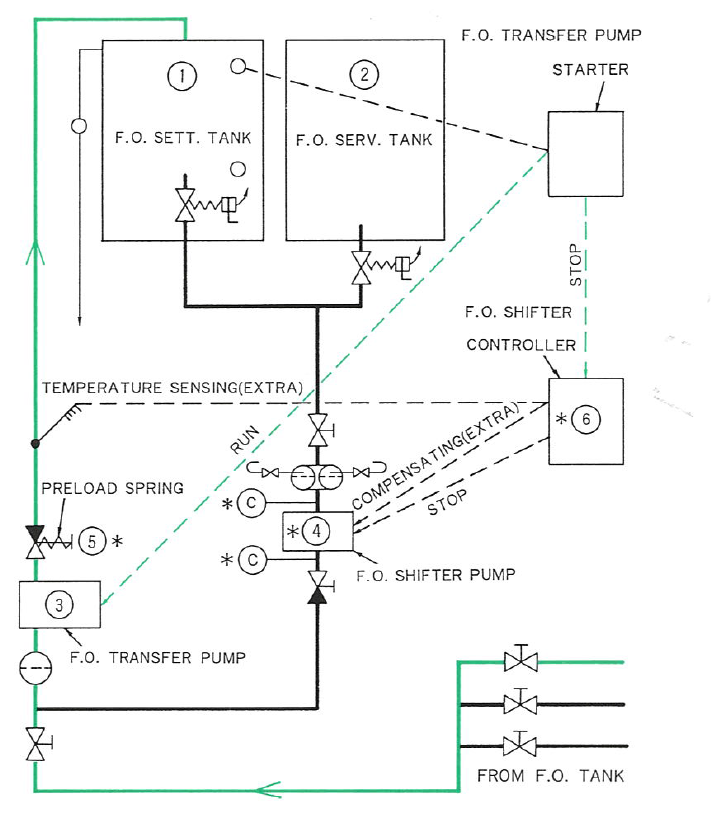

This system is an epochmaking one, which can shift C heavy fuel oil from storage tanks, such as double bottom tanks, to settling tank in the engine room without any expensive equipment as a boiler and heating coils in fuel oil storage tanks, which we have been needing in shifting C heavy oil until now.

This system is a process of heating the needed quantity of fuel oil by mixing with hot fuel oil, which is heated by heaters in settling tanks, purifiers, and service tanks and by special heater in engine room and removes back to the storage tank through strainer at the inlet side of the transfer pump, suction pipe, and suction bell mouth in storage tank.

This process is able to solve many problems about clogged strainer, resistance against sucking high viscosity fuel oil in the suction pipe lines, and checking flowing fuel oil at the suction bell mouth.

※ The features of Epochal System F.O. Shifter:

l. Boiler and heat ing coils in storage tank are not always in needs.

2. This system is easily installed at low expenditure.

3. Thermal collection efficiency is high and the effect of saving fuel oil is good.

4. Continuously blowing heated fuel oil from the service tank prevents sludges in fuel oil tanks from growing. Therefore the soils of fuel oil and combustion lines are took out. The expenditures about engine spare parts and maintenance are saved.

5. A conventional gear pump is able to be used for transfer pump.

6. T his system has quicker effect on heat ing than conventional heat ing coils system.

7. When a blender is used, the effect of blending is improved for the temperature at the supply of heated C heavy oil is not changeable.

8. Heat trace such as filter of stainer at the inlet side of shift pump, suction pipe, etc are not needed.

9. As the fuel oil surface temperature in storage tank (Double bottom tank under the cargo hold) does not raises high, the damages of the cargo by sweat and moisture are not done. (No Heat Damage)

10. Protect the Ballast tanks from heat erosion of heating influence of the adjacent F.O. tanks.

11. Even when the ship runs by 50% output, the steam consumption is covered by an exhaust gas economizer, for steams are not consumed for eating fuel oil in the F.O. storage tanks.

12. This system is in good order for being reasonably designed. This system takes less trouble for being automated.

13. Our system is flexible one for Owner's, shipbuilder's and chief engineer's opinions.

Team : Technology Development Team

In charge : S.K.Kwon Assistant Manager

Tel : 82-51-413-7701

E-mail : jmis@jonghap.co.kr

Conversion or Remodeling of passengers ships

- Maker

- KEYANG/SESHIN BUFFALO

- Major Product

- KEYANG/SESHIN BUFFALO

- Major Business

- Supply of KEYANG & SESHIN BUFFALO

- In charge

-

Headquarter(Namhang) Consulting

Senior

- Team :

- Technology Development Team

- In charge :

- P.H.Shin General Manager

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

Deputy

- Team :

- Technology Development Team

- In charge :

- J.B.Kim Assistant Manager

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

Revolution Machinery Division

Senior

- Team :

- Machinery & Plant Team

- In charge :

- Y.J.Son General Manager

- Tel :

- 82-51-413-4277

- E-mail :

- infoturbo@jonghap.co.kr

Deputy

- Team :

- Turbocharger Service Team

- In charge :

- J.K.Kim Plant Manager

- Tel :

- 82-51-413-4277

- E-mail :

- infoturbo@jonghap.co.kr

- Field practice

-

- Team :

- Ship & Machinery Repair Team

- In charge :

- I.B.Seo Senior Foreman

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr

- Reference

- Sample.xls

Repair of Naval ships & equipment (incl. subsea diving equipment)

- Maker

- DONGKUK STEEL Agency

- Major Product

- H-BEAM, PLATE, ANGLE, CHANNEL, ROUND BAR, FLAT BAR

- Major Business

- http://www.dongkuk.com

- In charge

-

Headquarter(Namhang) Consulting

Senior

- Team :

- Procurement & Supply Team

- In charge :

- J.O.Jang General Manager

- Tel :

- 82-51-413-7705

- E-mail :

- shipstores@jonghap.co.kr

Deputy

- Team :

- Procurement & Supply Team

- In charge :

- J.G.Kim Assistant Manager

- Tel :

- 82-51-413-7705

- E-mail :

- shipstores@jonghap.co.kr

Revolution Machinery Division

Senior

- Team :

- Turbocharger Service Team

- In charge :

- M.H.Park General Manager

- Tel :

- 82-51-413-4277

- E-mail :

- infoturbo@jonghap.co.kr

Deputy

- Team :

- Turbocharger Service Team

- In charge :

- S.J.Park Assistant Manager

- Tel :

- 82-51-413-7701

- E-mail :

- infoturbo@jonghap.co.kr

- Field practice

-

- Team :

- Ship & Machinery Repair Team

- In charge :

- D.S.Jung Senior Foreman

- Tel :

- 82-51-413-7701

- E-mail :

- jmis@jonghap.co.kr